Tube Cutting Machines

Redefining Precision and Productivity

Vulcan redefined high-speed tube cutting when we introduced the first chipless supported shear tube cutting machines, setting a new standard for precision and productivity. Our machines are engineered for maximum efficiency, delivering chipless, burr-free cuts at high speeds across a variety of applications. Trusted globally, Vulcan’s Brehm technology ensures top-tier performance, enabling manufacturers to achieve outstanding results with every cut.

What is Supported Shear Tube Cutting?

Supported shear tube cutting is a highly efficient process that uses two sets of punches and dies to ensure a clean, precise cut. The punches hold the inside diameter of the tube, while the dies secure the outside diameter. One set remains stationary while the other moves, gradually cutting through the tube until the remaining material shears cleanly—similar to how scissors work.

This method offers several key advantages: Burr-free cuts, No material distortion, Zero waste, High-speed operation.

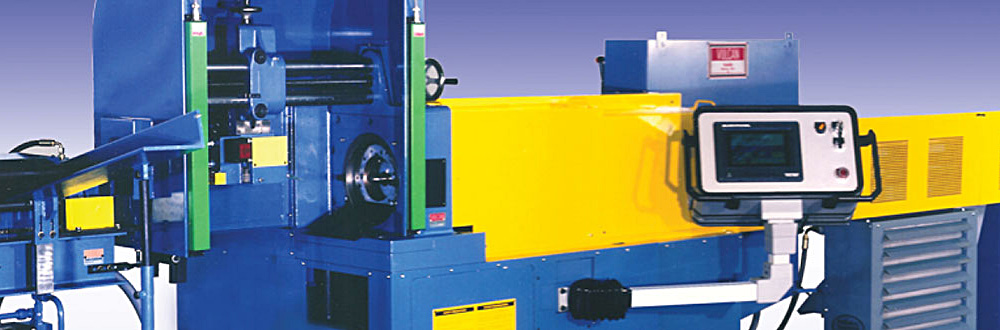

BREHM® TUBE CUTTING MACHINE

Vulcan Brehm Tube Cutters are known for high-speed burr-free cuts, that are used globally.

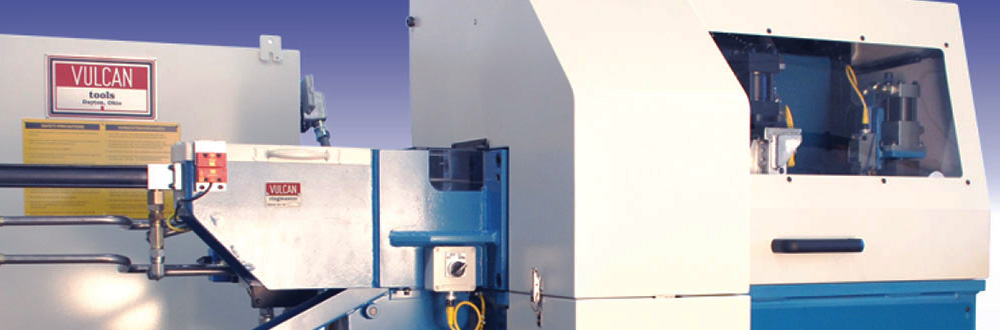

RINGMASTER TUBE CUTTING MACHINE

Vulcan Ringmaster is designed for high speed cut-off of tubing ranging from ½” OD up to 4” OD.