Waterjet Cutting

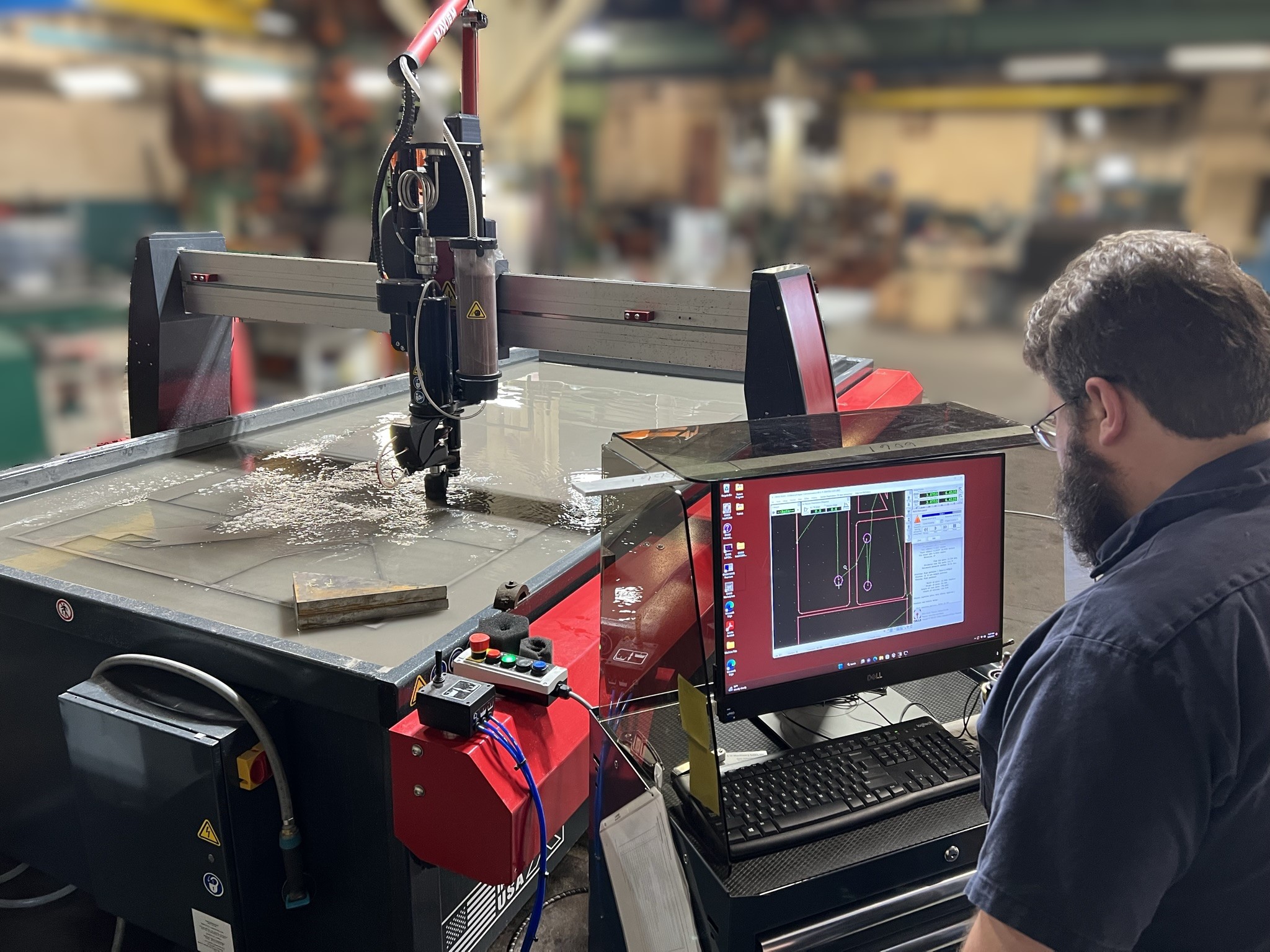

Advanced 5-Axis Waterjet Cutting in Dayton, Ohio

At our Dayton-based precision machining shop, we’ve transformed production capabilities with our 5-axis waterjet machine. By incorporating this advanced technology, we can significantly reduce production times while delivering precision and versatility for a wide range of projects.

Serving businesses across Ohio, including Columbus, Cincinnati, Springfield, and Middletown, as well as industries in Kentucky and Indiana, we provide top-tier waterjet cutting solutions.

Our 5-axis waterjet is ideal for industries such as aerospace, automotive, medical, electronics, defense, manufacturing, energy, and industrial equipment, offering cutting solutions tailored to meet the unique demands of each field.

The A-Jet Difference

True 5-Axis Cutting

Achieve complex bevel cuts, countersinks and weld-ready edges with ease. The A-Jet’s 60° range of movement and ±0.09° positioning accuracy ensures optimal precision, delivering exceptional results for high-tolerance projects.

Complex Part Fabrication:

Our waterjet technology makes it easy to create detailed flat parts with high precision, offering new possibilities for a wide range of applications.

Pre-Machining Benefits

Pre-machining stock before CNC milling reduces operations and cycle times, streamlining production.

Low-Temperature Cutting

The waterjet’s low-temperature process minimizes material stress and helps maintain flatness, making it ideal for delicate or heat-sensitive materials.

Advanced Drive System:

Featuring high-precision motion control with a magnetic linear encoder and electronic drive control, this system ensures micron-level accuracy for every cut.

Advanced Waterjet Cutting for Metals, Composites, and More

Metals

Aluminum, steel, titanium, copper, and more.

Composites

Carbon fiber and fiberglass.

Plastics

Acrylics, polycarbonate, and other polymers.

Ceramics

Tile and glass.

Others

Rubber, foam, and wood.

why Choose Our Waterjet Services?

High Precision

Ideal for intricate designs, complex geometries, and precise cuts on a variety of materials.

Efficiency

Complete many details in a single operation, reducing overall production time.

Versatility

Suitable for a wide range of materials, including metals, composites, and more.

Material Integrity

Our low-temperature cutting process avoids heat distortion, preserving material quality and structural integrity.

Customizable Options

Equipped with features like Terrain Follower for uneven surfaces and optional bulk abrasive delivery systems to minimize downtime.