Precision Machining

Precision Machining services Based in Dayton, Ohio

At Vulcan Tool Company, we specialize in precision machining through our fully equipped and versatile machine shop. Our facility handles a wide range of operations, including milling, turning, metal fabrication, cutting, and grinding. Serving customers in Dayton, Columbus, Cincinnati, Kentucky, and Indiana, as well as businesses across the USA, we are committed to providing high-quality machining solutions with precision and reliability.

Machining Services for Every Industry

Our machining services support a variety of industries, including automotive, aerospace, medical, construction, food processing, defense, oil and gas, agriculture, consumer goods, marine, and transportation.

Whether you’re in need of precision machining or general machining services, Vulcan Tool Company is your trusted partner for dependable and high-quality solutions.

Precision Machining Capabilities

CNC Milling & Turning

We provide custom CNC machining for both high and low-volume runs, offering multi-axis capabilities for precise, high-quality parts with tight tolerances and optimized efficiency.

Max machining capabilities

Milling 36″D x 60″W x 48″H

Turning 46″ swing, 20′ between centers

Manual Machining

We also provide manual machining services for custom projects requiring more specialized, hands-on techniques.

4 - 5 Axis Milling

Our 4-axis and 5-axis milling machines provide superior flexibility and precision, ideal for complex geometries and intricate designs.

Wire EDM & Ram EDM

Vulcan Tool Company is equipped with both Wire EDM and Ram EDM capabilities, offering high-precision cutting and shaping for hard-to-machine materials and intricate details.

Grinding Services

We offer precise grinding operations to achieve the desired surface finish and dimensional accuracy for a wide range of materials.

Reverse Engineering & Part Reproduction

Our reverse engineering services use measurement technology to precisely replicate obsolete or hard-to-source parts with exceptional accuracy. We offer precision solutions for CAD modeling, detailed dimensional analysis, and custom machining to ensure an exact match to the original specifications.

Comprehensive Machining Solutions

Custom details machined to print

Machined fixturing for production

Replacements for out of production parts

Reverse engineering and replication

Work with all types of metal and plastic

Machined injection molds

Lot sizes from one to one thousand

Machined weldments

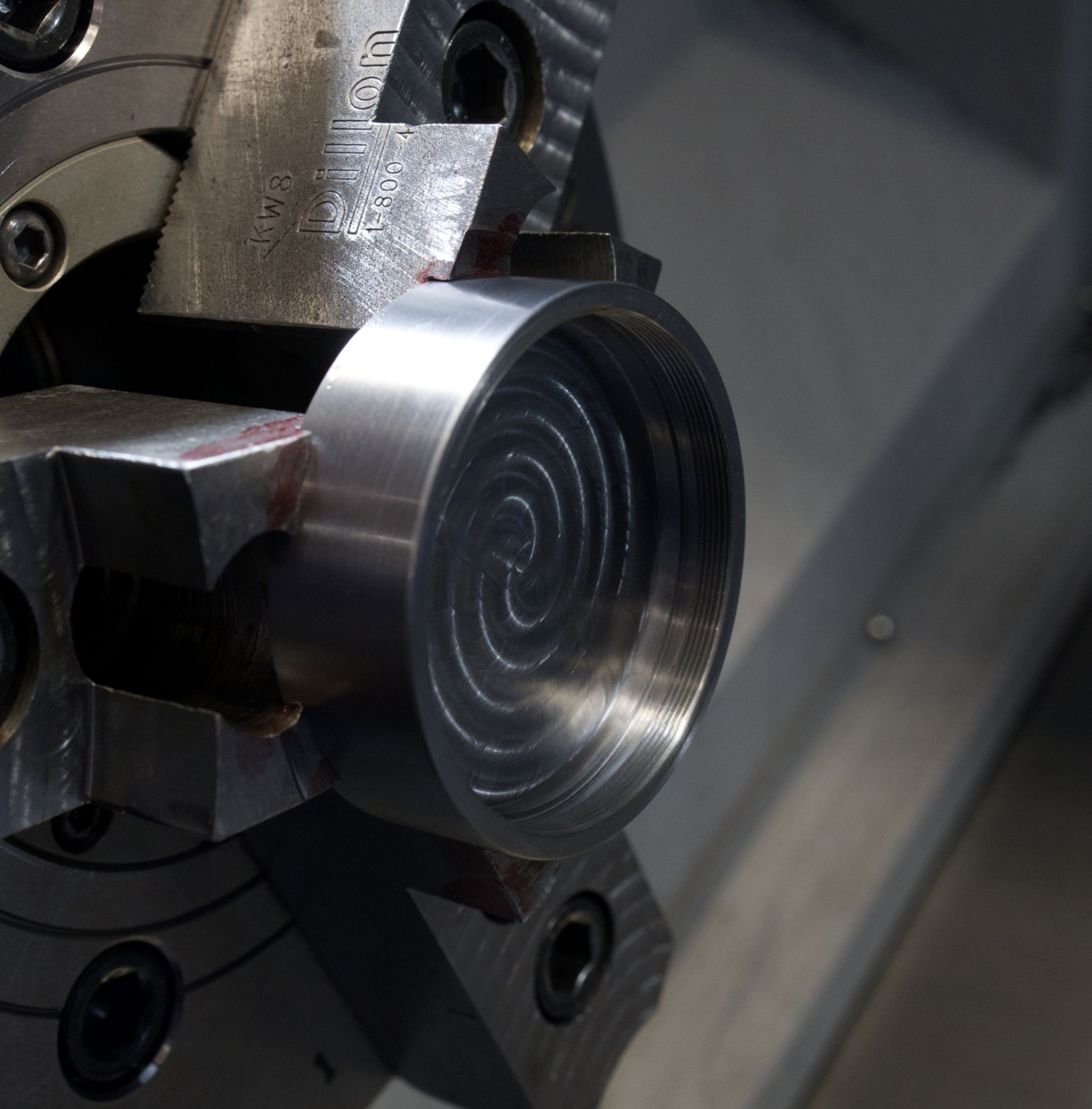

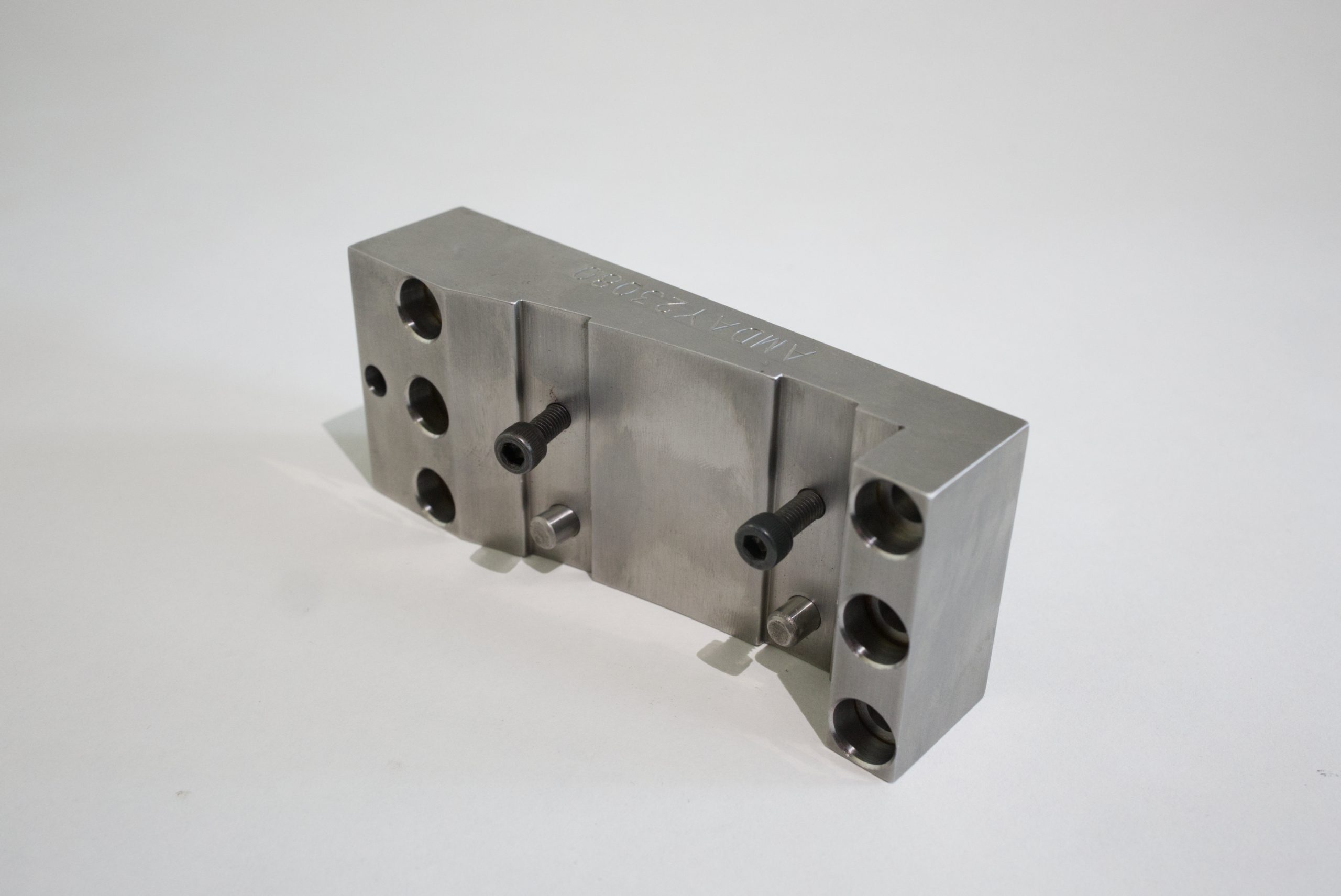

Precision Machining for Custom Parts

Some of Our Recent Projects in the Machine Shop

ADDITIONAL Capability

5-Axis Waterjet

We have been able to reduce production times on many machined parts by utilizing our 5 axis waterjet machine. Our A-Jet provides more sophisticated control and a greater range of part-production capabilities that goes beyond automatic taper compensation. Featuring 60° of movement with ±0.09° positioning accuracy, the A-Jet’s true 5-axis cutting makes countersinks, bevels and weld-ready edges easy to achieve. Even complex 3D parts such as propellers become possible with this technology.

“Pre-Machining” stock prior to CNC Mill can reduce operations and cycle time

Provides a low temperature cutting alternative to help maintain flatness

Many details can be completed with one operation on 5-axis waterjet