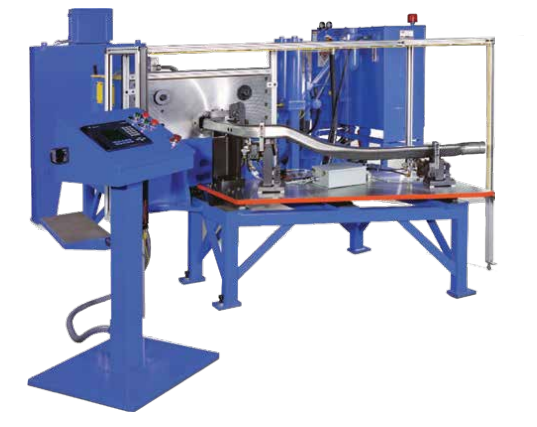

Hydroform Trimming Machines

Precision, Speed, and Reliability

Our Hydroform Trimming Machines offer trimming and notching capabilities for hydroformed tubes and components. Whether it’s long hydroformed frame parts, bent exhaust components, or custom shapes, our end trimmer machines are designed to handle the challenges that standard dies cannot accommodate. From precision trimming of tube to complex notching, our machines ensure high-quality results with speed and efficiency, making them ideal for high-volume production lines.

Hydroform End Trimmers for High-Quality Finishes

High Production

With the capability to process up to 300 tubes per hour, our machines ensure high output for even the busiest manufacturing environments. Whether you’re working with hydroformed frame components, bent exhaust parts, or custom tubular shapes, our machines optimize productivity without compromising on quality.

No Burrs

Achieve flawless results with clean trims free from distortions, burrs, or pinch-trim die marks. The precision ensures consistent output, making them ideal for industries requiring strict quality standards, such as automotive, aerospace, and defense manufacturing.

Automatic Operation:

Fully automated trimming processes allow you to trim one end or both ends of tubes efficiently. This feature not only saves time but also reduces manual labor, enhancing operational efficiency for high-volume production lines.

Long Production Life

Our machines are built to last, featuring dies that are easy to maintain and sharpen through simple grinding. This ensures extended production life and minimizes downtime, keeping your operations running smoothly with minimal maintenance costs.

Efficient Performance

From notches to curves and irregular shapes, our Hydroform Trimming Machines handle complex geometries with ease. Their versatility makes them the perfect solution for trimming hydroformed tubes used in diverse applications like ammunition casings, flare tubes, and specialized industrial components.

Ideal For

GRENADES

MUNITIONS

Automotive Parts

Industrial Conveyor System Components

FLARE CASINGS

AMMUNITION SHELLS

Aerospace Components

Muffler and Catalytic Converter Tubes