Jig Grinding Alternative: A Cost-effective solution for precision grinding

In the world of precision machining, jig grinders have long been the go-to solution for achieving ultra-precise hole grinding and finishing. However, the high cost and specialized nature of these machines make them impractical for many shops. Fortunately, there is a powerful jig grinding alternative that delivers comparable results at a fraction of the cost, the Vulcanaire Spindle Attachment, a high-precision grinding attachment that enhances existing equipment.

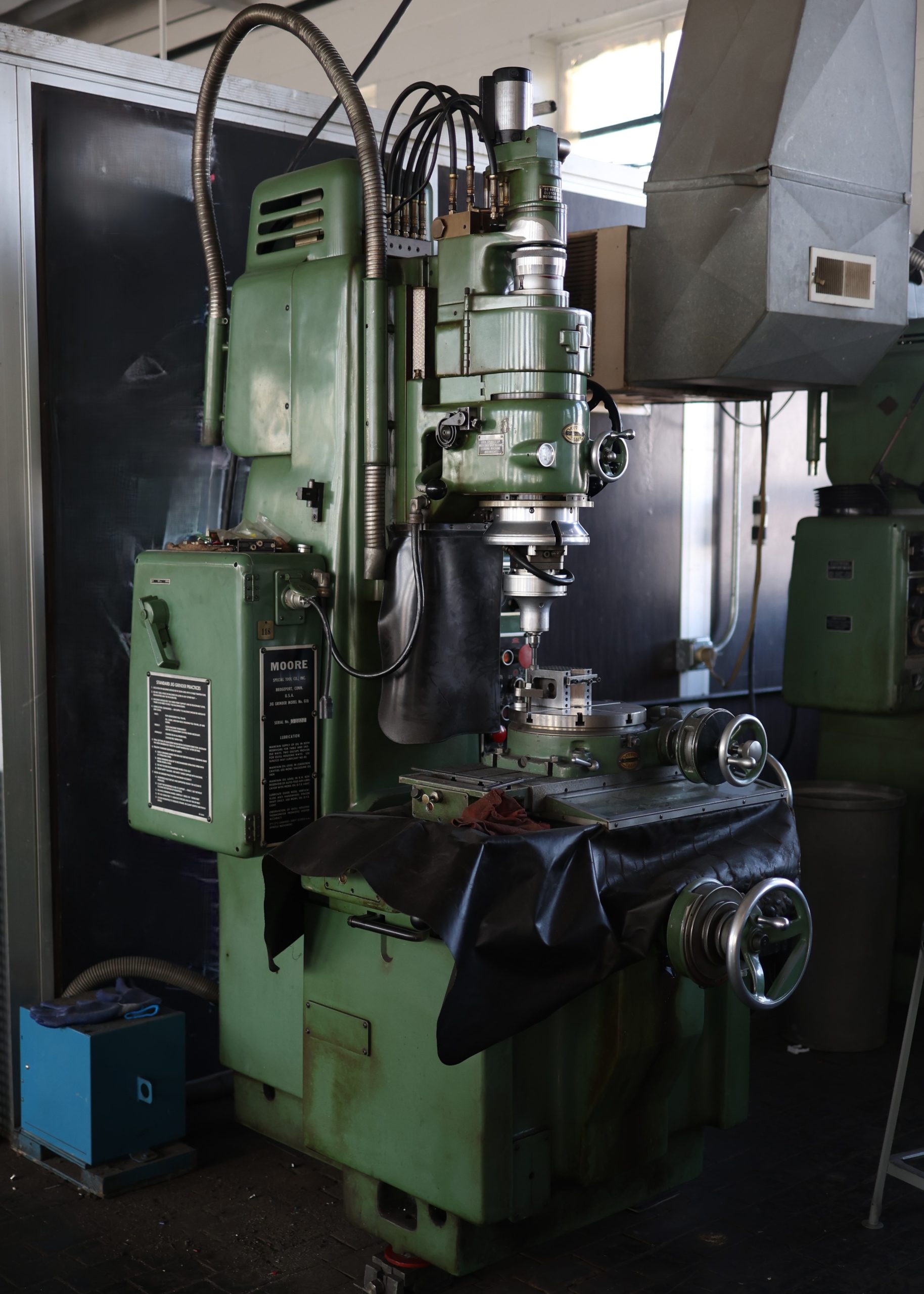

The Challenge: High Costs and Limited Accessibility of Jig Grinder

Jig grinders are highly specialized machines used for precision hole grinding and finishing, particularly in the aerospace, tool and die, and mold-making industries. While they offer unparalleled accuracy, their drawbacks include:

High Initial Investment

A dedicated jig grinder is expensive, making it a costly addition to most machine shops.

Specialized Training

Operating a jig grinder requires skilled technicians, adding to labor costs and training requirements.

Floor Space Requirements

As a standalone machine, a jig grinder takes up valuable shop space.

For many manufacturers, these limitations make it difficult to justify the purchase of a dedicated jig grinding machine. This is where the Vulcanaire Spindle Attachment provides an ideal alternative.

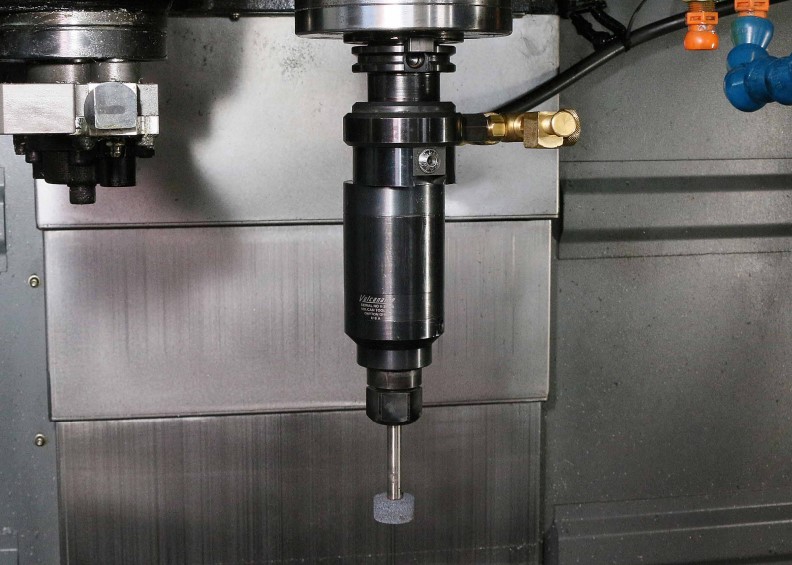

The Solution: Vulcanaire Spindle Attachment – A Versatile, High-Speed Grinding Option

The Vulcanaire Spindle Attachment transforms your existing mill or lathe into a high-speed manual or CNC jig grinder capable of precision grinding. Designed as an affordable and efficient alternative to a dedicated jig grinder, the Vulcanaire grinding spindle attachment delivers key advantages:

Cost Savings

A fraction of the cost of a full jig grinder, making high-precision grinding more accessible.

High-Speed Performance

Spindle speeds ranging from 4,000 to 300,000 RPM, allowing for precision hole grinding and fine surface finishing.

Easy Integration

Mounts directly to milling machines, lathes, and other equipment, eliminating the need for an additional standalone grinder.

Versatility

Compatible with abrasive, carbide, CBN, and diamond wheels, allowing for a wide range of grinding applications.

Precision Capabilities

Achieves tolerances to tenths of a thousandth (0.0001”), delivering exceptional accuracy.

CNC Compatibility

Serves as a CNC spindle upgrade, transforming your equipment into a CNC jig grinder for automated, high-speed grinding.

Why Choose the Vulcanaire Over a Traditional Jig Grinder?

While jig grinders remain essential in some high-end applications, the Vulcanaire Spindle Attachment offers an attractive alternative for machine shops looking to expand their grinding capabilities without the high price tag. It allows manufacturers to:

Perform precision hole grinding without investing in a separate jig grinder.

Reduce setup time and increase shop efficiency by using existing equipment.

Maintain the flexibility to handle a variety of grinding tasks

including ID grinding and OD grinding. For those considering a jig grinding machine vs spindle attachment, the Vulcanaire provides a jig grinder alternative that offers both affordability and adaptability.

A Practical Choice for Precision Machining

For manufacturers in industries such as aerospace, tool and die, medical device production, and general machining, the Vulcanaire Spindle Attachment provides a practical and economical solution for achieving precision comparable to a jig grinder—at a fraction of the cost. With its ability to integrate seamlessly with mills and lathes, this high-precision spindle attachment for milling machines offers an unparalleled combination of affordability, precision, and versatility.

If your shop is looking for an affordable jig grinding solution that delivers high-precision results without the high costs, learn more about the Vulcanaire Spindle Attachment to see how this tool can enhance your machining capabilities.