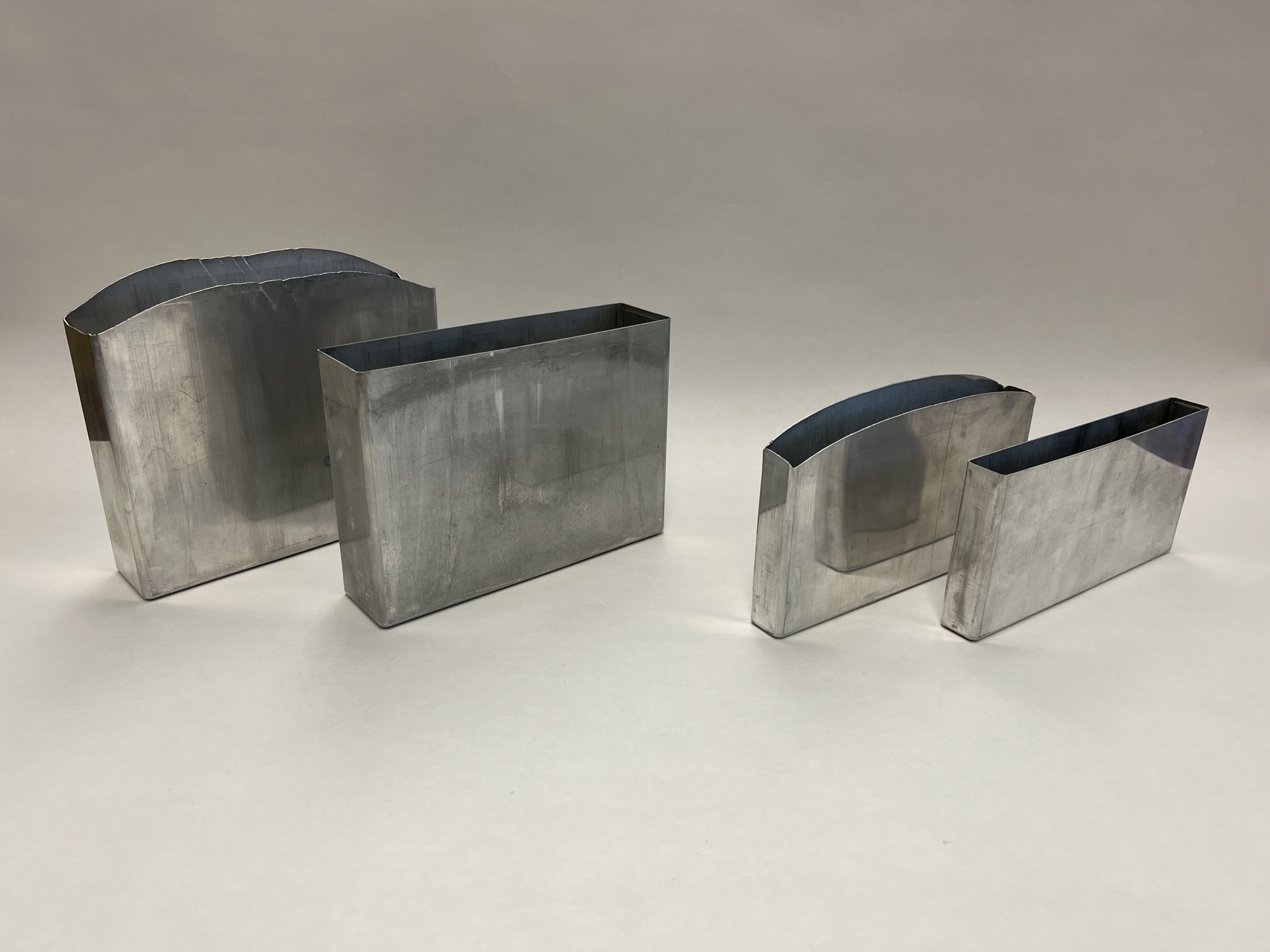

Shimmy Die Trim Tooling

Burr-Free & High-Precision Shimmy Trimming

Brehm® Shimmy™ Dies provide superior speed and accuracy for trimming stamped / drawn parts.

High production die can be used in conjunction with part transfer system and incorporated into a progressive die for high volume applications. Shimmy Dies are versatile; use the same basic die for new parts by simply ordering new adapters, which is much less costly than building a new die.

Tolerances are approximately ±0.001″.

Advantages

High Production

Achieve exceptional production rates with the ability to process up to 1,350 round shells per hour. For large, irregularly shaped parts and tubes, the capacity reaches up to 300 per hour, while motor housing covers can be trimmed at a rate of over 600 per hour.

efficient

Streamline your operations with one-stroke trimming, designed to handle notches, curves, irregular shapes, and more with precision and speed.

Production savings

Save on costs by using the same basic die for new parts. Simply adapt it with different tooling adapters to accommodate changing production needs.

No Burrs

Ensure superior quality with clean, smooth trims that are free of burrs, distortions, or unsightly pinch-trim die marks, reducing the need for secondary finishing.

Easy Integration

Seamlessly integrate the system into your existing metal stamping operations, including part transfer systems and progressive dies, for a smooth and efficient workflow.

LONG PRODUCTION LIFE

Maximize the lifespan of your dies with easy sharpening by grinding, keeping them in top condition for consistent, reliable performance.

What are the Benefits of a Shimmy Trim over a Pinch Trim?

Shimmy Trim controls flatness

In addition, notches and tabs can be incorporated into the trim function.

Shimmy Trim results in burr free parts

This eliminates the need for secondary de-burring operations.

Shimmy Trim is more precise

With consistent parts tolerances can be held as close as .001″.

Ideal For

PRISMATIC & CYLINDRICAL BATTERY CELL HOUSING

MOTOR HOUSING COVERS

CHASSIS

FRAME RAILS

SUPPORT RAILS

TITANIUM HOUSINGS

MEDICAL PARTS

CROSS-MEMBERS